Products

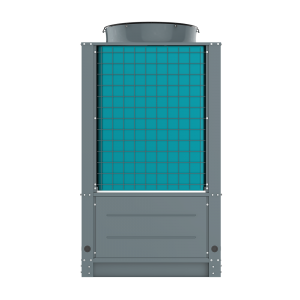

RP40W/01 Air Source Heat Pump Dryer For Tobacco Leaf

Product parameters

| Product name | Air Source Heat Pump Dryer |

| Model | RP40W/01 |

| Power supply | 380V3N~50Hz |

| Anti-shock level/protection level | Class I/IP×4 |

| Rated calories | 40000W |

| Rated power consumption/working current | 10000W/20A |

| Maximum power consumption/working current | 15000W/30A |

| Drying room temperature | 20-75℃ |

| Noise | ≤75bB(A) |

| High/low pressure side maximum working pressure | 3.0MPa/3.0MPa |

| Maximum working pressure on discharge/suction side | 3.0MPa/0.75MPa |

| The maximum pressure of the evaporator | 3.0MPa |

| Drying room volume | Below 65m³ |

| Refrigerant charge | R134a (3.1x2)kg |

| Dimensions (L×W×H) | 950×950×1750(mm) |

| Net weight | 248kg |

Kind tips

1. When the machine is turned on for the first time or the shutdown time is long, the machine must be connected to the power supply, and the compressor of the unit can be preheated for at least 2 hours before starting the machine to avoid damage to the compressor.

2. After the unit has been running for a period of time, regular maintenance must be carried out with reference to the "Installation, Operation and Maintenance Manual".

3. The installation, maintenance and maintenance of the unit must be carried out by trained professionals, and only various spare parts provided by the company can be used.

Features of the unit

1. The operation management of the unit is automatically completed by a microcomputer and controlled by a touch screen;

2. The unit adopts an integrated structure mode, which can better cooperate with the drying room renovation project;

3. The control logic is completely implemented in accordance with the No. 418 document of the State Tobacco Office, and the roasting farmers can quickly master it;

4. The temperature curve mode of the baking room, the expert curve of the upper, middle and lower smoke technology, the self-set curve, the automatic and manual equipment of each baking part are all implemented in accordance with the spirit of the document;

5. Intelligent defrosting;

6. Adopt Copeland brand compressor.

Application field

The curing room is an important facility for tobacco production. The state attaches great importance to the technological innovation and technological improvement of tobacco production including the facilities and equipment of the curing room, and keeps track of the development of new tobacco curing technologies including heat pumps. According to preliminary understanding, there are currently nearly 20 heat pump barn manufacturers in my country that only use electricity as energy. The equipment they produce varies in specifications. Manufacturers continue to carry out equipment and technology upgrades through test demonstrations. The row effect is steadily improving.

The heat pump barn has the advantages of energy saving, emission reduction, quality improvement and efficiency improvement, which meets the requirements of green development and the future development direction of the barn. In the tobacco industry, there are constraints that have not yet been widely promoted: no unified product standard, power supply, initial investment major issues.

About our factory

Zhejiang Hien New Energy Equipment Co., Ltd is a state high-tech enterprise incorporated in 1992,. It began to enter the air source heat pump industry in 2000, registered capital of 300 million RMB,as a Professional manufacturers of development, design, manufacture ,sales and service in the air source heat pump field.Products cover hot water, heating, drying and other fields. The factory covers an area of 30,000 square meters, making it one of the largest air source heat pump production bases in China.

Project Cases

2023 the Asian Games in Hangzhou

2022 Beijing Winter Olympic Games & Paralynpic Games

2019 artificial island hot water project of the Hong Kong-Zhuhai-Macao Bridge

2016 the G20 Hangzhou Summit

2016 the hot water •reconstruction project of Qingdao port

2013 Boao Summit for Asia in Hainan

2011 Universiade in Shenzhen

2008 Shanghai World Expo

Main product

heat pump、air source heat pump、heat pump water heaters、heat pump air conditioner、pool heat pump、Food Dryer、Heat Pump Dryer、All In One Heat Pump、Air Source solar powered heat pump、Heating+Cooling+DHW Heat Pump

FAQ

Q.Are you a trading company or manufacturer?

A: We are a heat pump manufacturer in China.We specialized in heat pump design/ manufacturing for more than 12 years.

Q.Can i ODM/ OEM and print my own logo on the products?

A: Yes, Through 10years research and development of heat pump, hien technical team is professional and experienced to offer customized solution for OEM,ODM customer, which is one of our most competitive advantage.

If above online heat pump does not match your requirements, please do not hesitate to send message to us, we have hundreds of heat pump for optional, or customizing heat pump based on demands, it is our advantage!

Q.How do l know if your heat pump are good quality?

A: Sample order is acceptable for testing your market and checking our quality And we have strict quality control systems from raw material incoming until finished product delivery out.

Q.Do: you test all the goods before delivery?

A: Yes, we have 100% test before delivery. If you need any assistance, please feel free to contact us.

Q: What certifications do your heat pump has?

A: Our heat pump have FCC, CE, ROHS certification.

Q: For a customized heat pump, how long is the R&D time (Research& Development time)?

A: Normally, 10~50 business days, it depends on requirements, just some modification on standard heat pump or a totally new design item.